Description

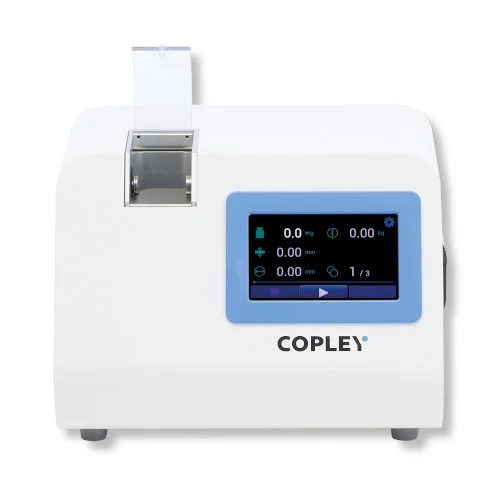

Tablet Hardness Tester-TBF 100i Copley UK

Key Features:

- Intuitive menu structure enables users to locate features quickly and easily

- Batch progress displayed during batch testing run provides clear indication on throughput status

- Easy-set user-configurable test parameters:

– Rate of force application (mm/min)

– Force measurement unit (N, kp, kgf, or lbs)

– Tablet Batch size - Key tablet measurements clearly displayedon-screen to user:

– Tablet weight (if applicable)

– Tablet thickness (if applicable)

– Tablet diameter (if enabled)

– Tablet hardness - Resistive touchscreen interface can be operated with gloves on

Test Apparatus & Method

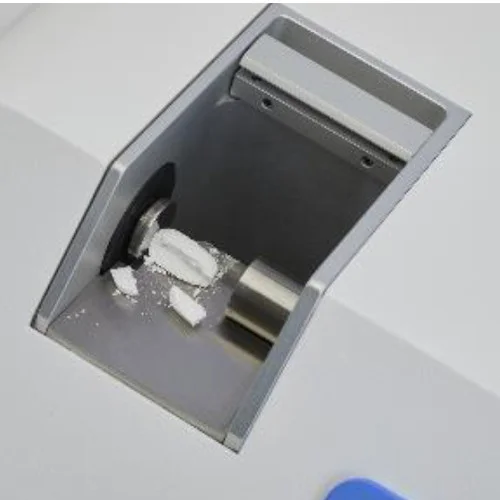

A tablet is placed between two platens (jaws), one of which is attached to a force gauge with load cell and the other to a motor which provides the mechanical drive.

The motorised jaw drives forward pressing the tablet against the fixed jaw until the tablet breaks. The motorised jaw then retracts and the load force required to break the tablet is recorded. The units of force normally employed to quantify breaking force are Kiloponds (Kilogram-Force) or Newtons.

Reporting

Extensive data output options are available as standard, including direct printing from the TBF 100i and direct reporting to a PC.

Reported parameters:

- Individual Tablet Results:

– Diameter (if enabled)

– Hardness

– Weight (if applicable)

– Thickness (if applicable) - Tablet Batch Statistics – Batch minimum, maximum, mean and standard deviation of:

– Diameter

– Hardness

– Weight

– Thickness - Calibration Data

– Calibration date

– Temperature calibrated at (°C)

TBF 100i Compliance & Maintenance

- Certificate of compliance to Ph. Eur./USP provided as standard

- Comprehensive IQ/OQ/PQ documentation packages and toolkits available

- Optional calibration rig available with a passcode-protected static calibration routine

- Latest calibration information stored and available to print

Choice of tablet breaking force measurement units:

- Kilograms (Kg)

- Kiloponds (Kp)

- Newtons (N)

- Pounds (lbs)

Tablet Measurements

- Breaking force (hardness)

- Diameter

- Weight (optional)

- Thickness (optional)

Passcode Protection

- Both load speed and fracture detect percentage are configurable, but are passcode protected to prevent unauthorised personnel from adjusting set values

Tablet Breaking Force Background: Tablet Hardness Test

- Allows quantification of hardness/robustness of tablet

- Checks consistency of mechanical properties of the tablet after manufacture

- Measurement requires breaking of tablet between two jaws and measuring force

- High hardness may indicate:

- Longer disintegration time

- Low dissolution levels

- Low hardness may indicate high friability

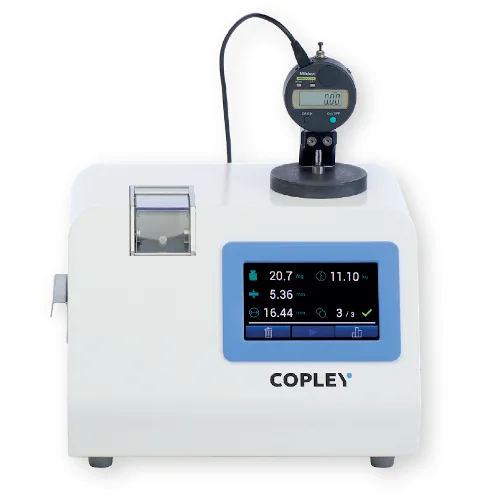

Tablet Weight & Thickness

With the addition of a balance and/or Mitutoyo micrometer for measuring thickness, the TBF 100i becomes a complete system for measuring the hardness, diameter, weight and thickness of tablets. This configuration is a highly efficient, cost-effective alternative to more sophisticated commercial systems for measuring these critical tablet parameters.

Alternatively, tablet weight and thickness can be entered into the TBF 100i system manually.

Technical Data:

| Pharmacopoeial Compliance: | · Ph.Eur. Chapter 2.9.8 Resistance to crushing of tablets

· USP Chapter <1217> Tablet Breaking Force. |

| User Interface | Resistive touchscreen |

| Max. Tablet Diameter | 36 mm |

| Force Range | 0 – 490 N |

| Force Application | Constant speed 1 – 50 mm/min |

| Hardness Units | N, kp, kgf, lbs |

| Testing Throughput

|

~ 5-8 tablets per minute* *depending on hardness/diameter of tablet under test |

| Fracture Detect Percentage | Adjustable between 30% – 90% |

| Data Output:

|

· RS 232

· USB type B (for communications with a PC) · In-built thermal printer |

| Waste Drawer | Integrated |

| Statistics Reporting: | Yes |

| Batch Testing: | Yes |

| Portable: | No |

| Unit Dimensions (w x d x h): | 283 x 237 x 208 mm |

Reviews

There are no reviews yet.